As a clean renewable energy, photovoltaics occupies an important position in the future energy structure. As the photovoltaic industry expands its investment scale, its pace of technological innovation is also accelerating, and the automation rate of production lines is increasing rapidly. Therefore, in the practical application of silicon wafer production in the photovoltaic industry, equipment manufacturers will inevitably face such a problem - the particularity of photovoltaic wafers makes it difficult for ordinary sensors to detect stably

Nowadays, AKUSENSE’s new blue light photoelectric sensor ESB-BY30 can solve these problems!

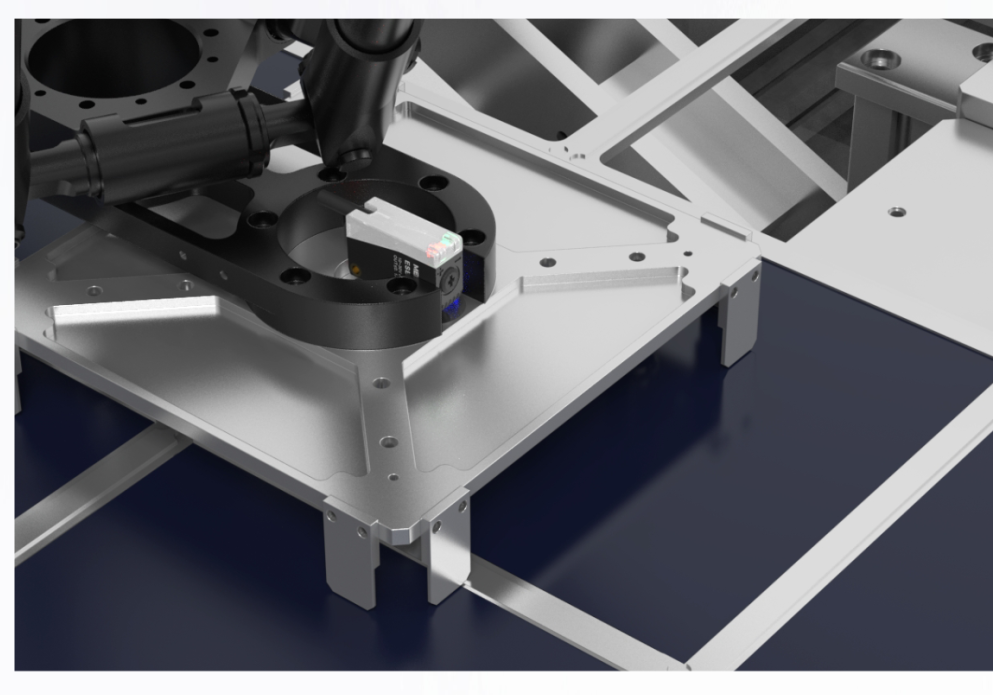

In this issue, we will share the application of new blue light photoelectric sensors in photovoltaic silicon wafer production~

Scenario requirements

From the upstream to the midstream of the photovoltaic industry, in various silicon wafer automation equipment, it is very important to detect whether the silicon wafer is in place/presence; a stable and efficient sensor needs to be selected for detection.

solution

Analysis of detection points

1. The nature of silicon wafers is a high-brightness + highly reflective object. Traditional red light sensors cannot measure enough reflected light, making them difficult to detect;

2. The reflectivity of the silicon wafer will change greatly after chemical treatment (such as cleaning, diffusion, etching, etc.)

Recommended selection

ESB-BY30N

Blue light photoelectric sensor

1. Choose blue light diffuse reflection photoelectric sensor ESB-BY30N, 465nm wavelength modulated blue light, short wavelength, high energy, blue light spot is clearly visible

2. Because solar cells have higher reflectivity in the blue range, the shorter wavelength of blue light can resist absorption. The blue light source provides reflective capabilities and increases the amount of light returned to the sensor, thereby achieving stable detection.

3. The blue-light photoelectric ESB-BY30N has excellent background suppression function and is not affected by the reflectivity of the silicon wafer during the detection process, ensuring the reliability of silicon wafer detection.

4. Built-in 6-turn potentiometer adjustment, fine adjustment of sensitivity can be made, everything is under control

5. Three circuit protection mechanisms (power reverse polarity protection, surge protection, short circuit protection) to effectively protect the sensor

6. The response time is ≤1.5ms, which can easily adapt to the rhythm of rapid production.