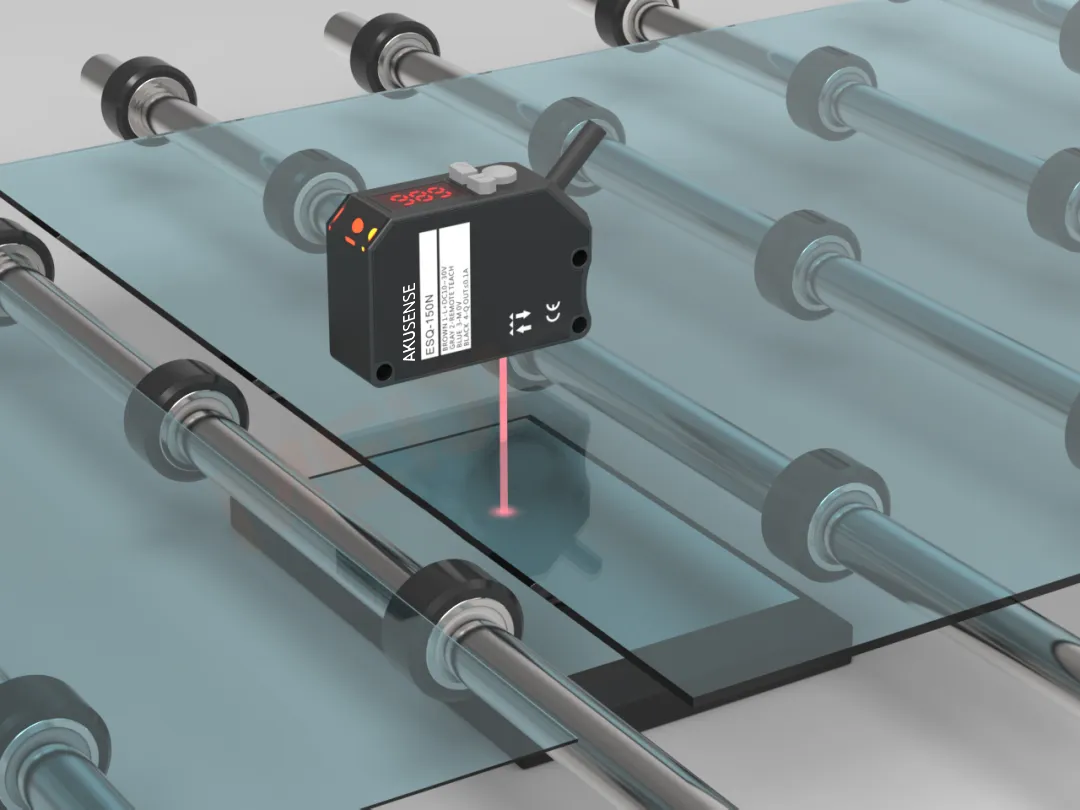

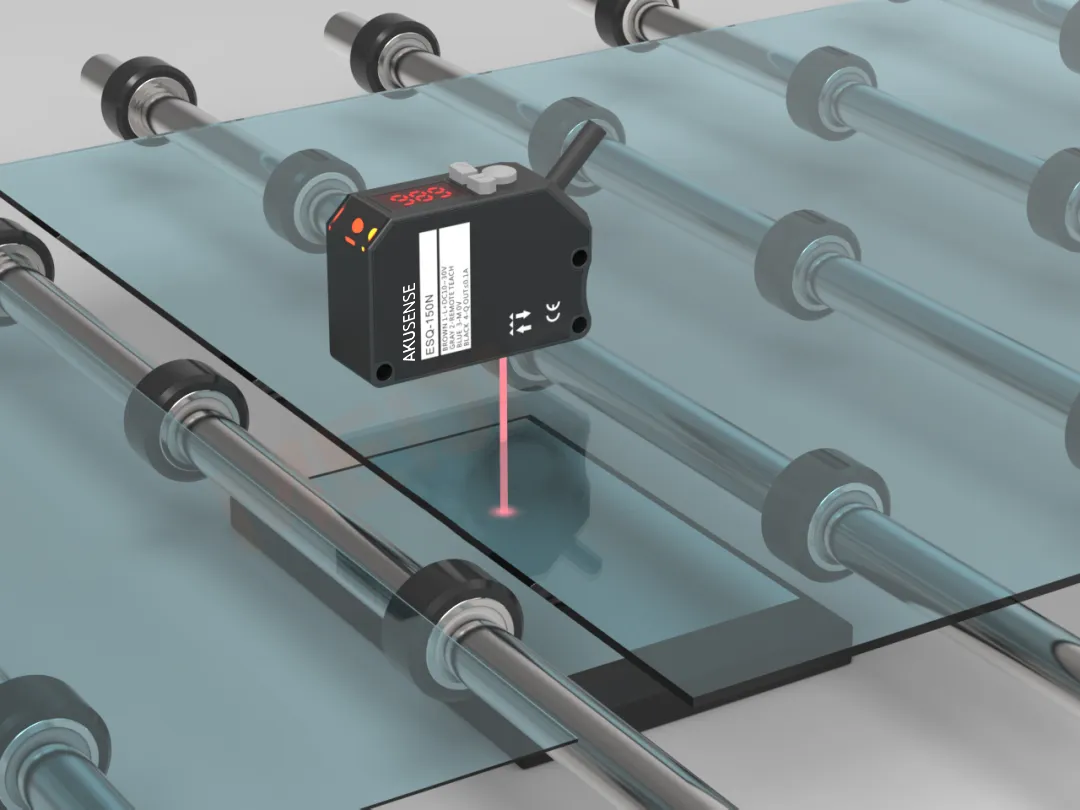

We often see these marks on the packaging of sensors (as shown in the picture below). When choosing sensors, users should give priority to products with these certification marks to ensure that the sensors can meet application requirements and ensure the safety of personnel and equipment. .

AKUSENSE has a complete product certification system. We can often see these logos on product packaging. Do you know what these logos mean? Today I will give you a simple popular science~

What is CE certification?

CE certification is the abbreviation of European unified Conformite europeenne. It is a safety certification necessary for products to enter the EU market rather than a quality certification. It is regarded as a passport for manufacturers to open and enter the European market. It is the European Union's safety control certification that ensures the most basic safety of products, that is, it is limited to basic safety requirements in terms of products not endangering the safety of humans, animals and goods.

There are many types of products on the market, and CE certification includes (SIL safety, ATEX explosion-proof, CPR building materials, PED pressure vessels, PPE personal protection, MD machinery, LVD-low voltage, EMC-battery compatibility, NOISE noise, RED unlimited instructions, TOYS toys, EN71 testing, ROHS, REACH, etc.), E-mark certification, RoHS certification, GS certification, EN/IEC testing)

Common ones include CE-EMC, CE-MD, and RoSH certification. Different types of products require different certification instructions and test specifications. Therefore, Meiji can also provide other certification requirements according to user needs.

What is UL certification?

UL certification is the abbreviation of Underwriters Laboratories Inc., which is one of the world's largest private institutions engaged in safety testing and identification.

In the course of more than 100 years of development, it has formed a strict organizational management system, standard development and product certification procedures. It is an independent, non-profit, professional organization that conducts experiments for public safety. It uses scientific methods to study and determine whether various materials, devices, products, equipment, buildings, etc. are harmful to life and property; it determines, compiles and issues corresponding standards and information that help reduce and prevent losses to life and property. . At the same time, it carries out research business, product safety certification and business safety certification business. Its ultimate goal is to provide the market with products with a considerable safety level.

In fact, for manufacturers, UL provides the most credible product safety testing and certification, because UL's standards represent not only "American standards", but also "international standards" that everyone has agreed upon.

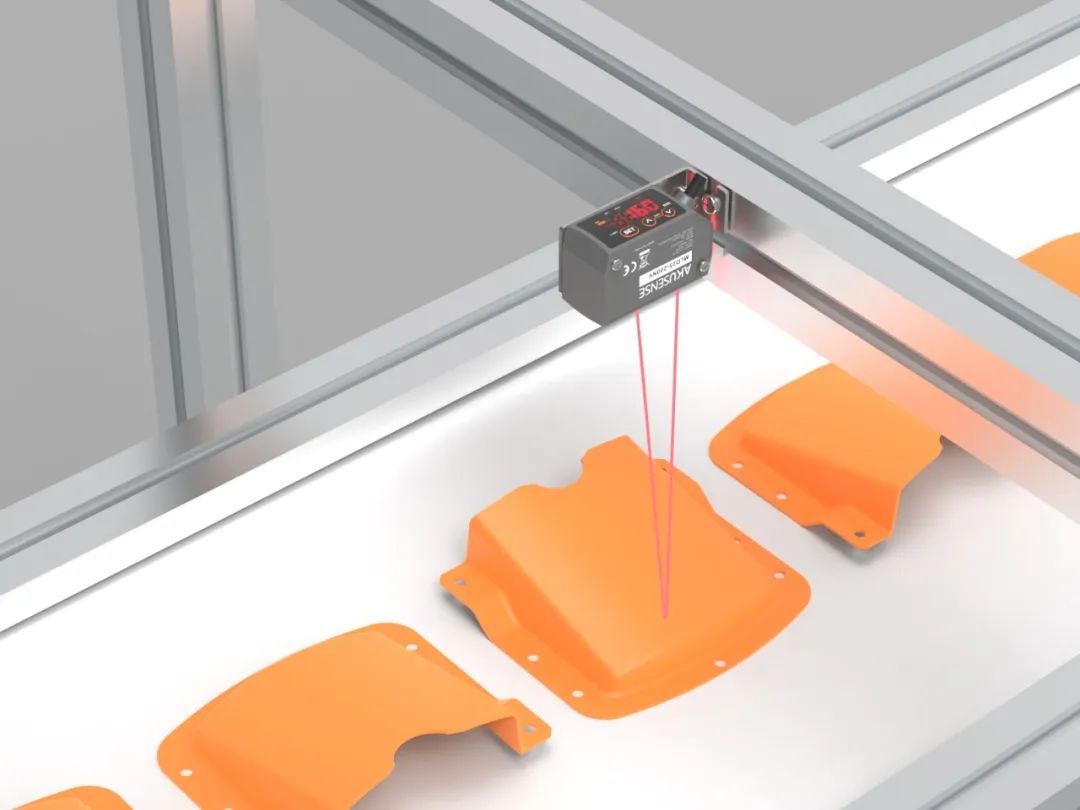

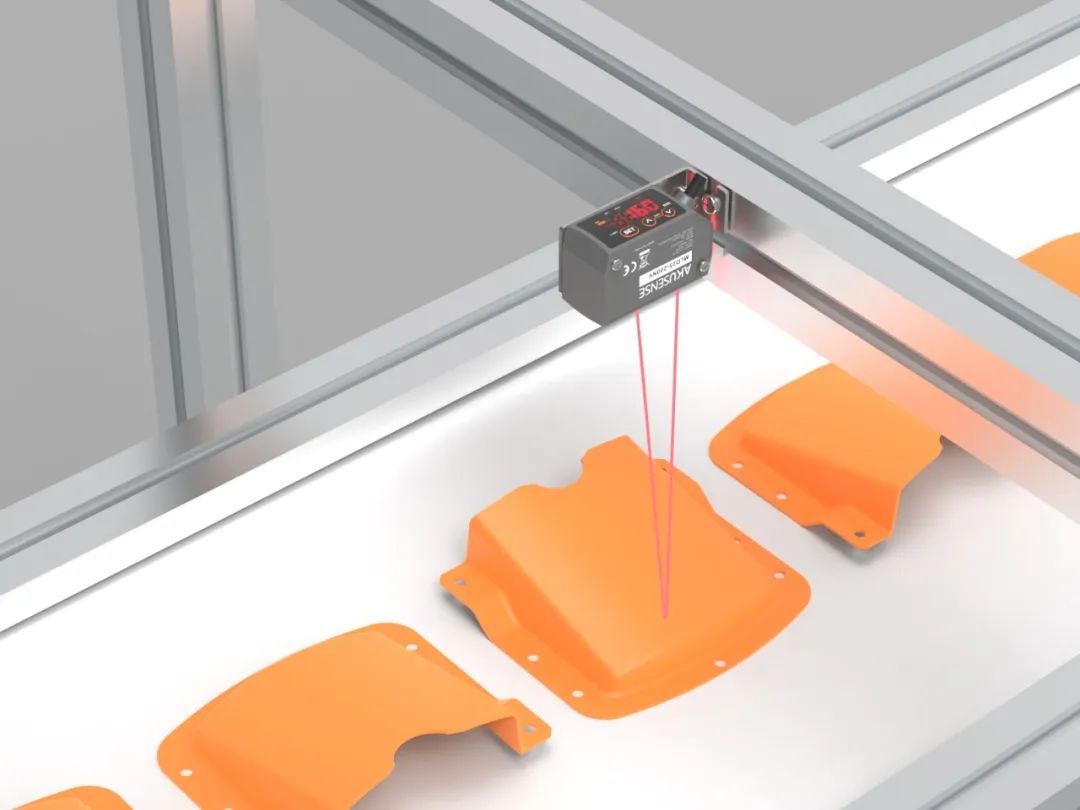

Recently, AKUSENSE precision optoelectronics series has obtained this certification:

What is REACH?

REACH testing is a strict chemical substance supervision measure implemented by the European Union, which is called "Registration, Evaluation, Authorization and Restriction of Chemicals". This regulation requires companies to register, evaluate, authorize and restrict the chemical substances they produce, sell or import into the EU market to ensure the safety of these substances to human health and the environment.

The core purpose of REACH testing is to conduct a comprehensive risk assessment of chemical substances and take necessary measures to manage those substances that may pose risks to health and the environment. The testing content covers the physical and chemical properties, toxicity, ecological impact of the substance, and its safety during production and use.

What is TUV certification?

This symbol is often seen on safety light curtains

TÜV certification is a safety certification mark issued by the German TÜV agency (Technischer Überwachungsverein, the German Technical Supervision Association). This certification is mainly aimed at component products, but it is not limited to this. Its scope of certification is actually very broad, covering many fields such as quality management, environmental management, energy management, and food safety.

In terms of product certification, TÜV certification aims to convey the consistency and compliance of the product to consumers and customers by evaluating the quality, reliability and safety of the product. During the certification process, products undergo rigorous testing and review, including but not limited to the strength and durability of materials, the reliability of the manufacturing process, and the functionality of the finished product. Products certified by TÜV are often regarded as a symbol of high quality, trustworthiness and safety.

Summarize

For products to be sold and circulated in the market, they must meet the requirements of the local market. During the production and use of industrial sensors, in order to ensure their safety, reliability and compliance with relevant standards, they usually need to undergo a series of certifications. These are trade barriers that the market has set up for products to ensure the safety and environmental protection of products in the local market.

In addition to the above general certifications, some specific industries may also have special certification requirements for sensors. For example, in the automotive electronics industry, sensors may need to pass AEC-Q series certification, which is designed to ensure the reliability, durability and performance of automotive electronics. In the medical industry, sensors may need to comply with certification requirements from relevant agencies such as the FDA (U.S. Food and Drug Administration).

The specific processes and requirements for these certifications may vary by certification body and product type. Generally speaking, the certification process includes application submission, product testing, factory inspection (if necessary), certification decision and certificate issuance. At the same time, in order to maintain the validity of certification, certified companies may also need to conduct follow-up work such as regular supervision inspections and product consistency inspections.