Recently, the hottest thing in the automotive industry is Xiaomi SU7. The number of units sold exceeded 88,898 within 24 hours of its release. With the support of this overwhelming traffic, it is also a severe test for the production line capacity of Xiaomi automobile factory. Xiaomi Automobile will respond to this big test with a comprehensive automation rate of more than 91%, a key process automation rate of 100%, and a 40 SU7 car super factory per hour when the production capacity is reached.

Source | Xiaomi Auto

At the Gigafactory site, you can see AMR robots running all over the floor pulling medium and large items, robotic arms waving their arms for automatic assembly, and intelligent quality inspection systems that replace human eye recognition. So in this issue, Xiao Ming will start with the intelligent quality inspection system that replaces human eye recognition, and share the application of Meiji Sensing Vision Solutions in visual inspection of automotive parts~

01 Detect the motor rotor

Whether to install wave pad

Application scenarios

After the rotor is transported to the inspection station and stops at the designated position, the workpiece is inspected.

Testing requirements

1. Determine whether the rotor is equipped with a wave pad

2. The background is more complex. It is necessary to exclude the influence of the rotor on the image and cause false detection, and the optimal grayscale threshold needs to be adjusted.

3. The waveform pad is an irregular circle with different degrees of reflection. It is necessary to avoid false detection caused by this structure and the optimal grayscale threshold needs to be set in coordination with the background.

Selection analysis

1. The position of the waveform pad is fixed, the detection range is small, and only presence or absence detection needs to be performed. The detection background is complex, and the height of the waveform pad is different, and it is easy to misdetect when using other sensors.

2. If the line laser method is used for detection, the cost will be relatively high and the complexity of the mechanism will also be increased.

3. Can replace manual detection quickly and accurately

4. Can produce stable output for a long time.

5. The detection method is non-contact and will not contaminate the product.

Selection and testing results

The visual standard product VDS10-BQ0106-WP was selected for detection. The detection results are as follows:

When the waveform pad is installed correctly, imaging can identify the presence of target spots.

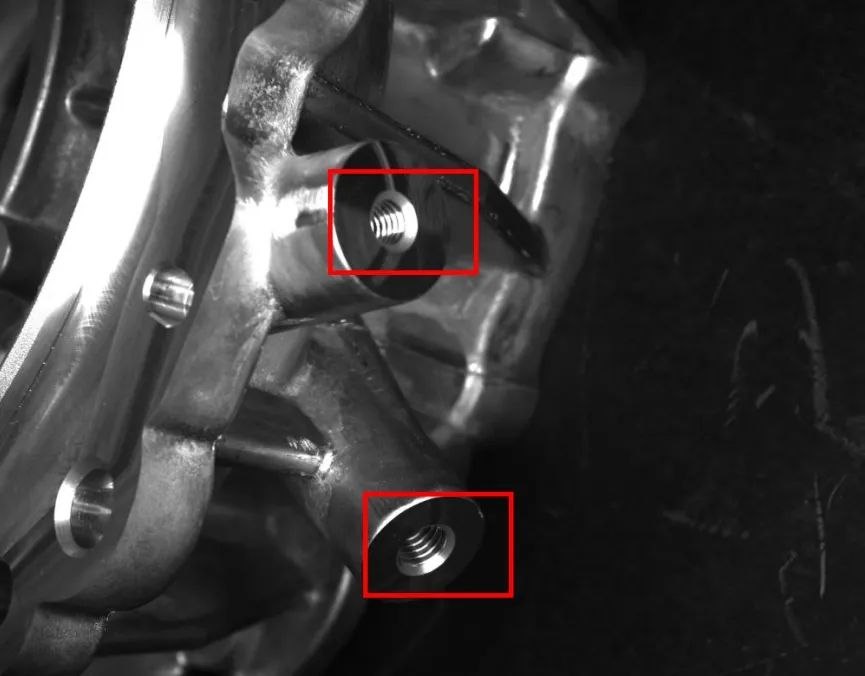

02 Whether the parts have threads or not

Application scenarios

It is required to accurately detect whether there are threads in the screw holes of product components; to accurately identify whether there are threads in the screw holes. If there are threads, the OK signal is executed and the product enters the next process for inspection; if there are no threads or holes in the screw holes, an alarm signal is output to the mechanical actuator to eliminate defective products.

Testing requirements

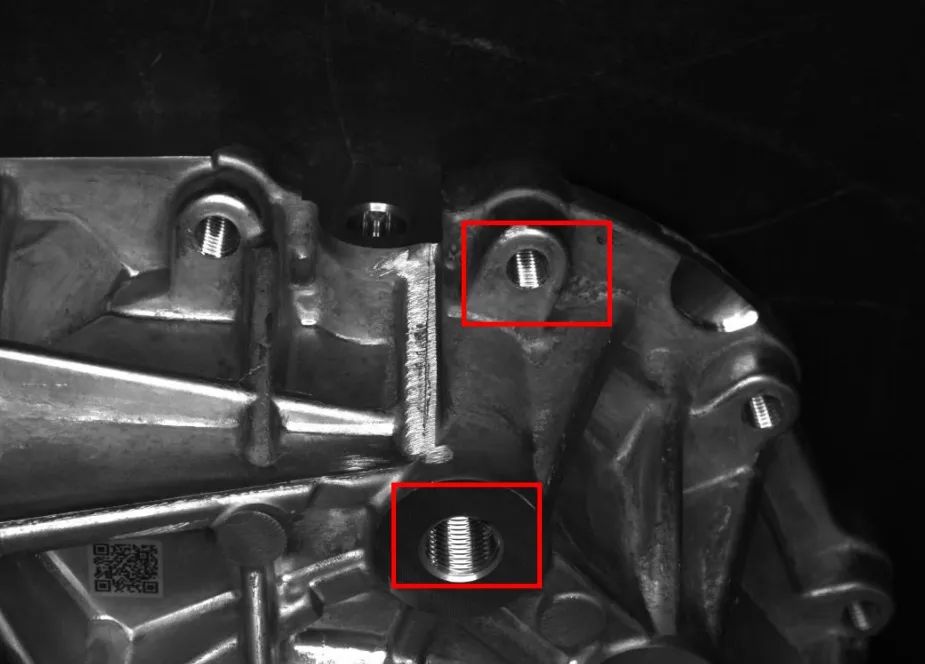

1. Frontal high and low step hole detection/cutting inspection

The workstation detection here requires a camera to detect two holes at the same time, and there is a height difference of about 5cm between the two holes and a large difference in the size of the holes. The depth of field needs to be considered when imaging.

2. Detection of single raised hole on the side

Single hole detection, larger size

Two holes with large side angle deviations

The two holes protrude in two directions respectively, and the size of the holes is not much different.

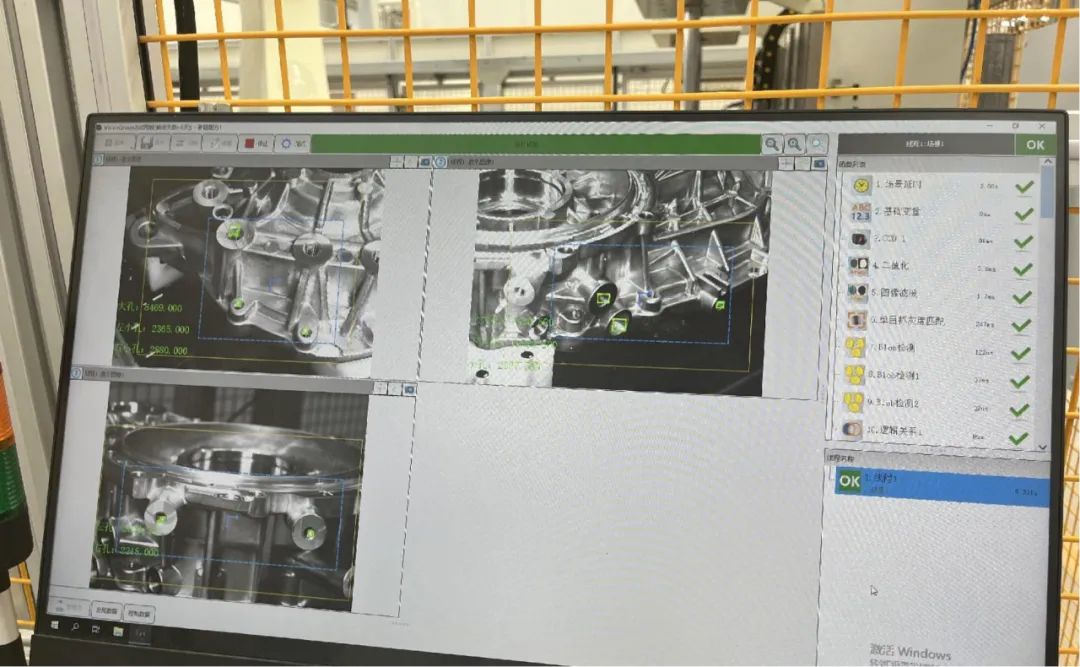

Selection plan

After building a visual mechanism to take pictures of the sample and test it, we can achieve good imaging effects with the above hardware configuration. Then we analyze the detection algorithm on the imaging pictures to obtain detection results that meet the requirements.

Using the VG-BR050-DA12 vision sensor solution, 20,000 products were tested during the test run, with 0 abnormalities; it has now been officially put into use in large quantities.

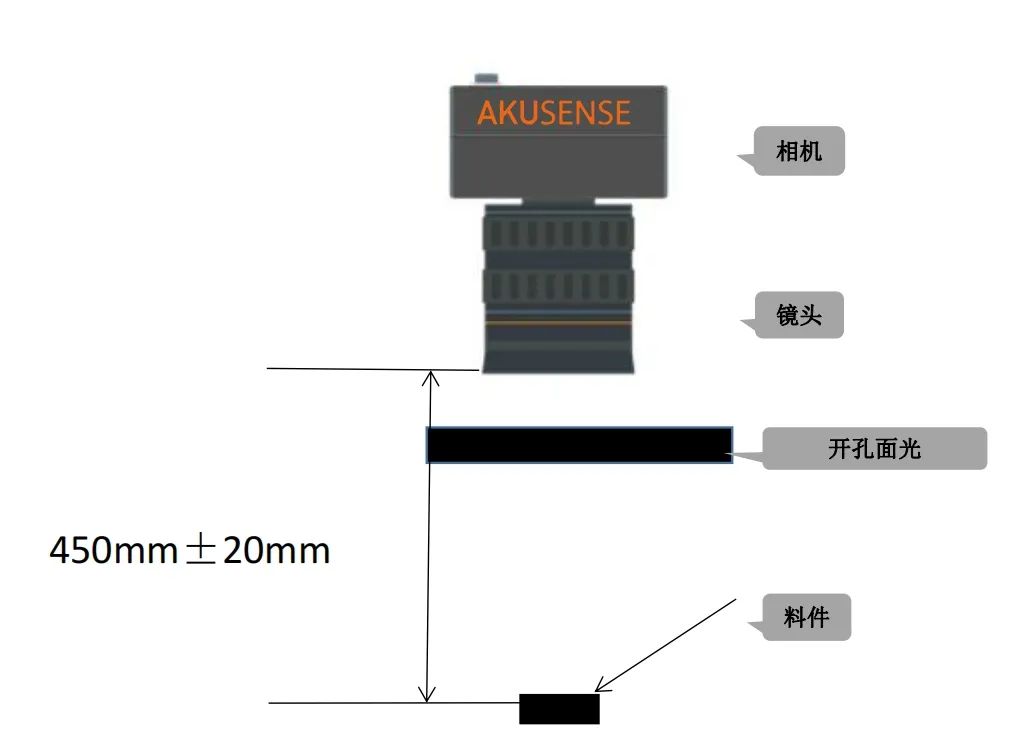

1. Cutting inspection station on the front face

The light source should be facing the workpiece, and the camera light source and the workpiece should be kept as vertical as possible.

Installation structure diagram

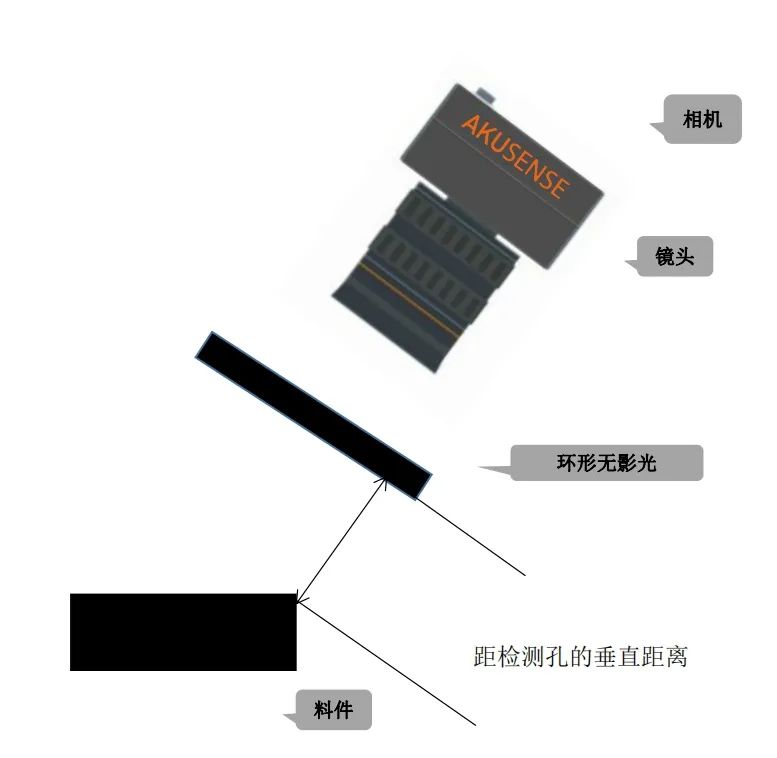

2. Single-hole detection and two-hole detection stations with different directions

The installation distance is 200±20mm, and the installation angle (high angle) between the camera and the workpiece needs to be determined according to the actual installation position. For hole detection with step differences, the installation distance is 270±20mm. It is necessary to determine the installation angle between the camera and the workpiece according to the actual installation position.

Installation structure diagram

Imaging effect

OK

High and low step holes (threaded)

NG

High and low step holes (no thread)

OK

Two holes with a large difference in angle (threaded)

NG

The red box is cut, and the yellow box is uncut.

Machine vision technology is an indispensable part of the implementation of artificial intelligence in the field of automobile manufacturing. Meiji Sensing will use advanced machine vision technology to improve the intelligent level of automobile manufacturing and realize the production process through high-precision identification, detection and judgment. Automation and optimization allow cars to transform from "manufacturing" to "intelligent manufacturing".