How to make cell phone screen automatic dispensing equipment achieve high precision and high efficiency.

How to make cell phone screen automatic dispensing equipment achieve high precision and high efficiency.

How to make cell phone screen automatic dispensing equipment achieve high precision and high efficiency.In the manufacturing and assembly process of smartphones, traditional threads and snaps can no longer meet the characteristics of ultra-thin, ultra-light, three-dimensional and aesthetically pleasing. In order to achieve a seam-free, flat and thin appearance, many manufacturers prefer to use dispensing technology for bonding and attaching smartphone components in the process of assembling phones.

In the process of dispensing, due to the fluid characteristics of glue, manual dispensing will have uneven glue, glue overflow, glue closure and other problems, but also the existence of the uneven level of operator skills and production shift on the stability of product quality; accurate, fast automatic dispensing machine came into being, equipment dispensing fine control and high consistency, efficiency is several times the manual dispensing or even A dozen times more efficient than manual dispensing, which greatly saves the cost pressure of enterprises, and more avoid the waste of glue and slow manual dispensing. Today, Xiao Ming will share with you the application of sensors in the cell phone screen double glue dispensing equipment.

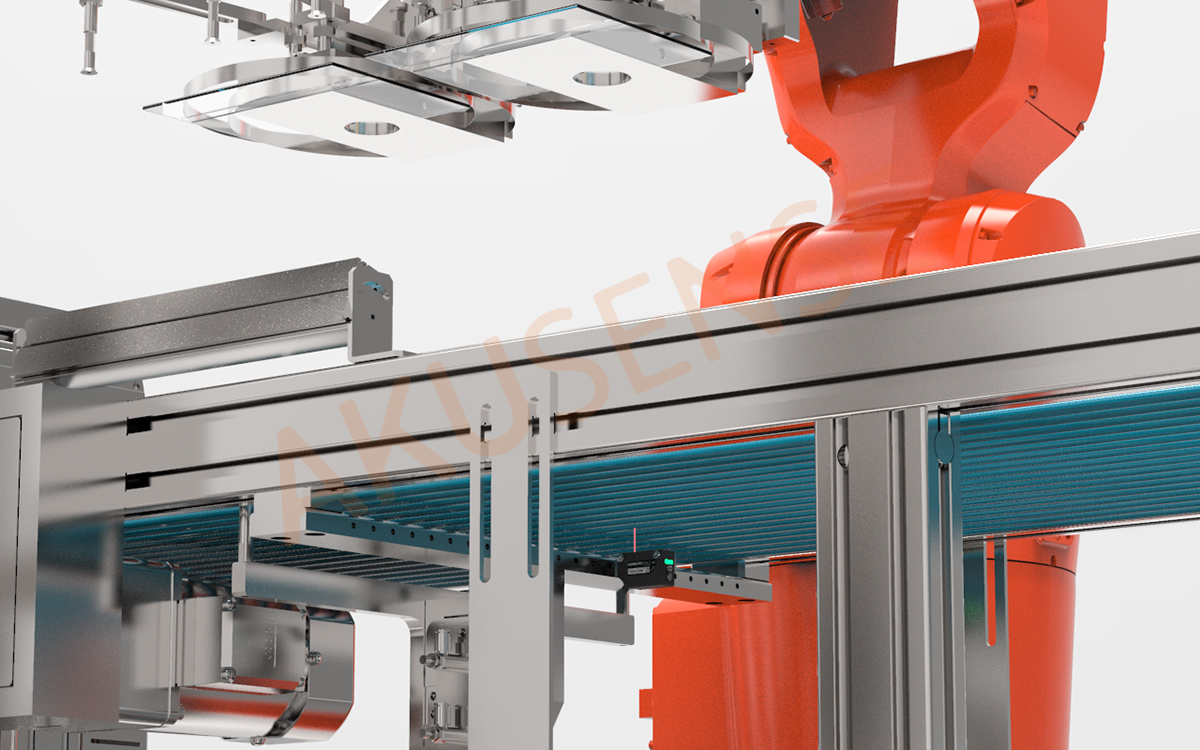

The double glue dispensing machine introduced in this issue is a fully automatic dispensing equipment for cell phone screen, the main function is to realize UV dispensing and blue glue dispensing for cell phone screen, UV dispensing adopts Musashi type spray valve, blue glue uses Sejong valve for dispensing. The whole cell phone screen dispensing process realizes automatic operation from product loading, positioning, dispensing to curing and discharging.

01 Loading material in place - background suppression type photoelectric

A background suppression type photoelectric sensor is installed directly below the front of the product position of the loading line body to detect cell phone screen loading. In order to meet the needs of different customer groups, there are more and more trendy colors in the cell phone frame, such as: white, black, pink, blue, and even gradient of other colors, it is necessary to use sensors that can detect any color objects, here the background suppression type photoelectric ESB-V30N is selected, using multiple anti-light interference technology, which can effectively resist the influence of ambient light; position type light signal receiver, which can suppress the background impact; has the advantage of better adaptability to meet the application of a variety of scenes.

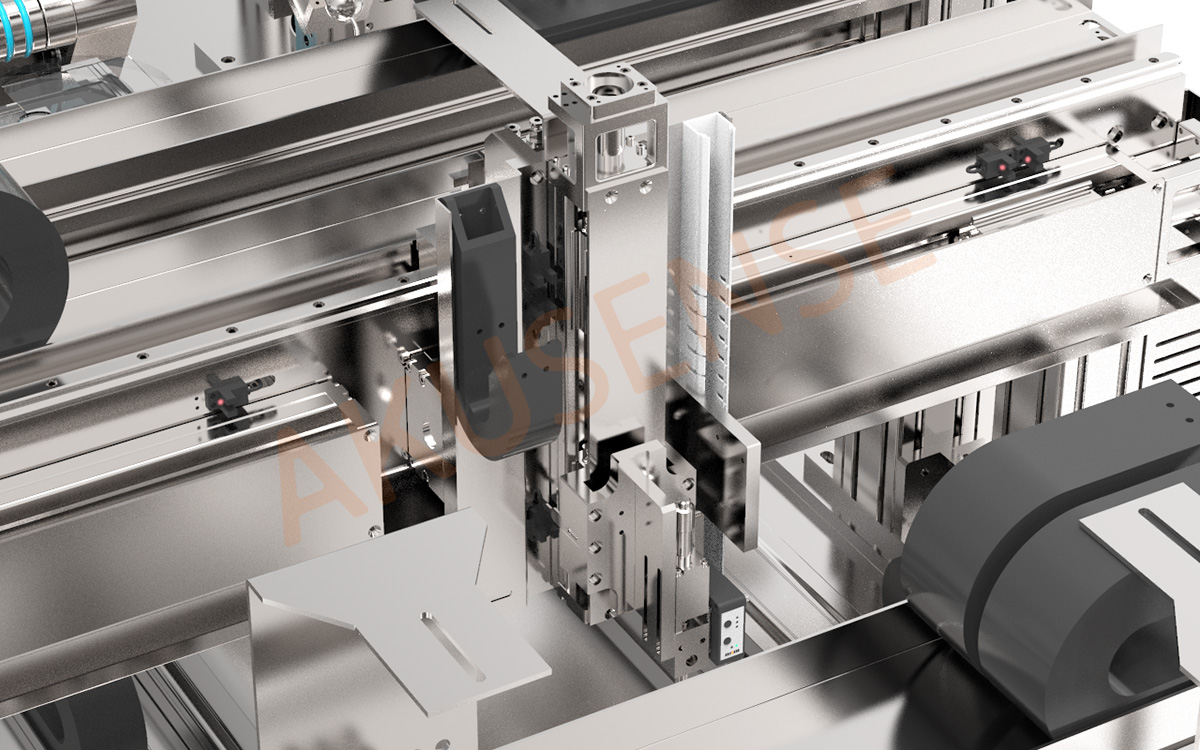

02 Dispensing and dispensing mechanism module - Slotted photoelectric

The slotted sensor is installed at both ends of the mechanism module, as the "joint" of the mechanism, to precisely control the home position and limit position of the mechanism movement, and the chip integrated design ensures the consistency of the product performance and the positioning accuracy of 0.01mm.

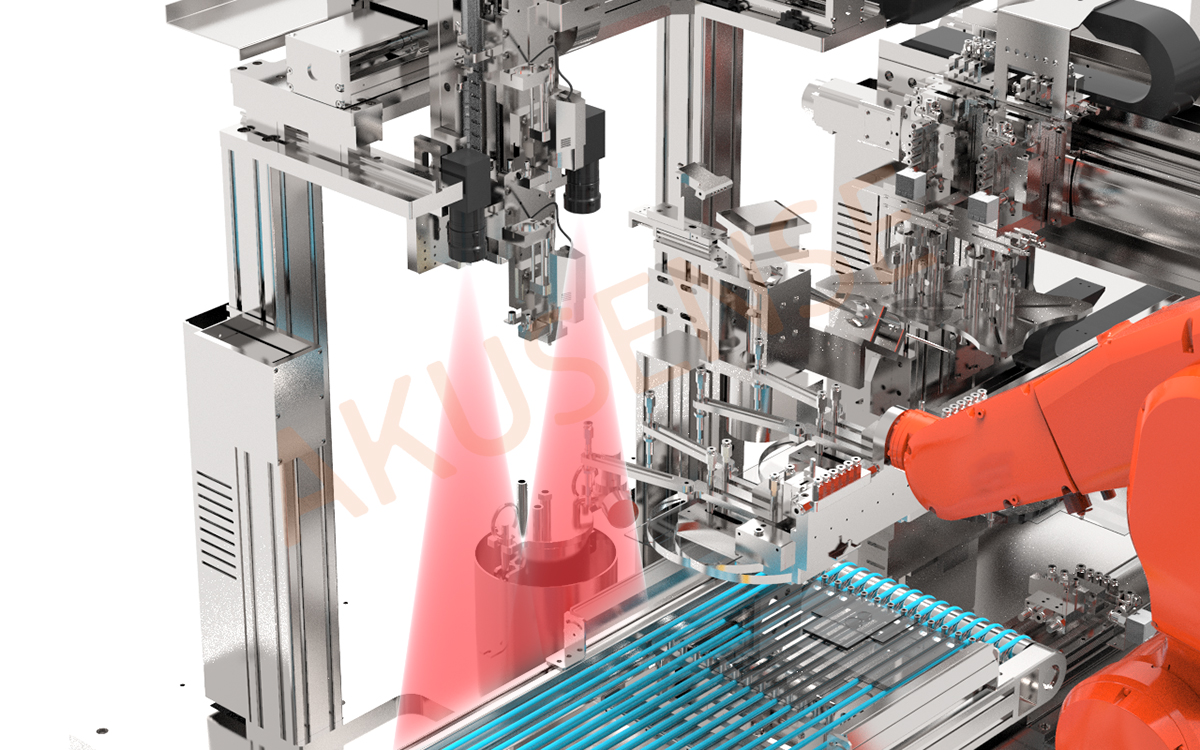

03 Product mark positioning - Vision detect

The camera will be installed above the uv dispensing station for cell phone screen mark identification and positioning. Due to the diversity of cell phone mid-frame, it is not possible to simply use a set of parameters to deal with all of them, which requires customizing the corresponding matching parameters for the product differentiation. For the straight edge processing is relatively simple, but for the area of round-arc intersection or gradient, it is necessary to use software algorithm to optimize the processing, remove some interfering factors and put The correct feedback value corresponds to the actual trajectory of the product one by one, so that the glue can be spotted in the right position.

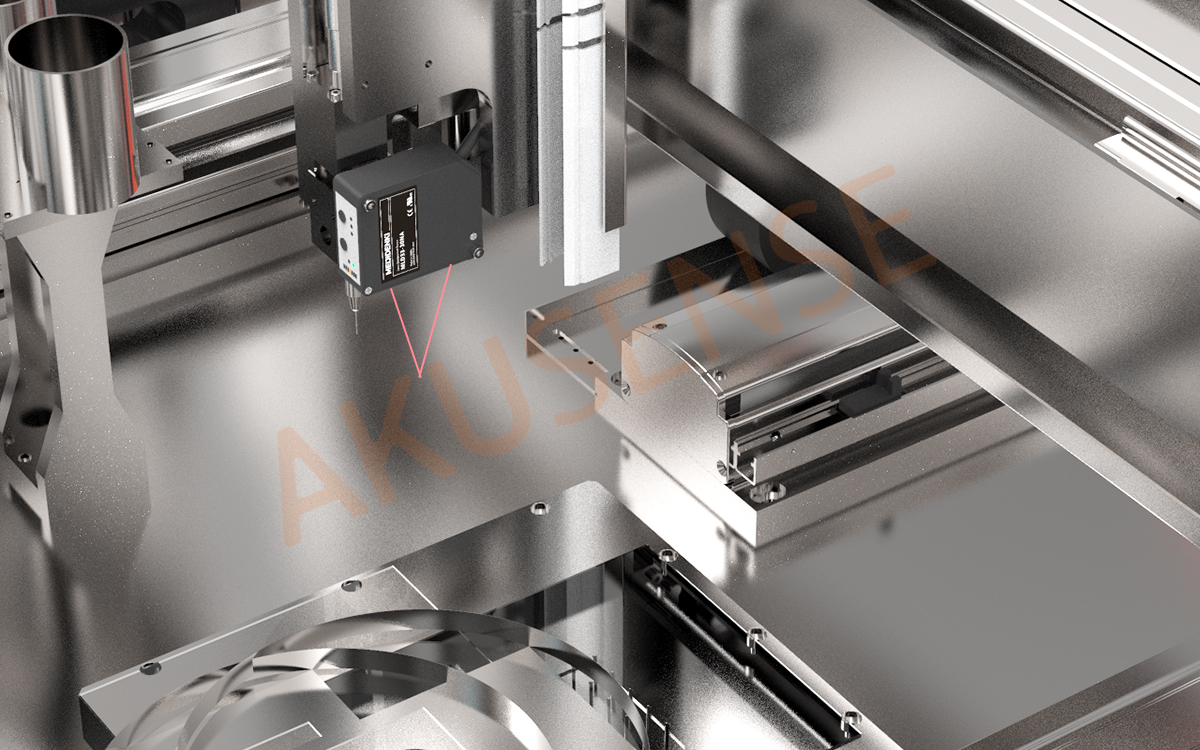

04 Height measurement of cell phone screens at dispensing stations - Laser displacement sensor

Equipment in accordance with the set coordinate system for the entire bezel dispensing, requiring good uniformity of dispensing, can not have pile up, can not have leakage, the width of the dispensing should be moderate, pile up will make the excess glue overflow or stick to the circuit board causing problems hidden, leakage of glue will make the bezel and the back pressure screen combined surface gaps may make dust, water stains immersed.

The laser displacement sensor MLD33-L is mounted on the same mechanism with the dispensing head, and the height of the cell phone screen is detected by the displacement sensor to control the dispensing height of the two heads, which can meet the requirements of micron-level detection accuracy.

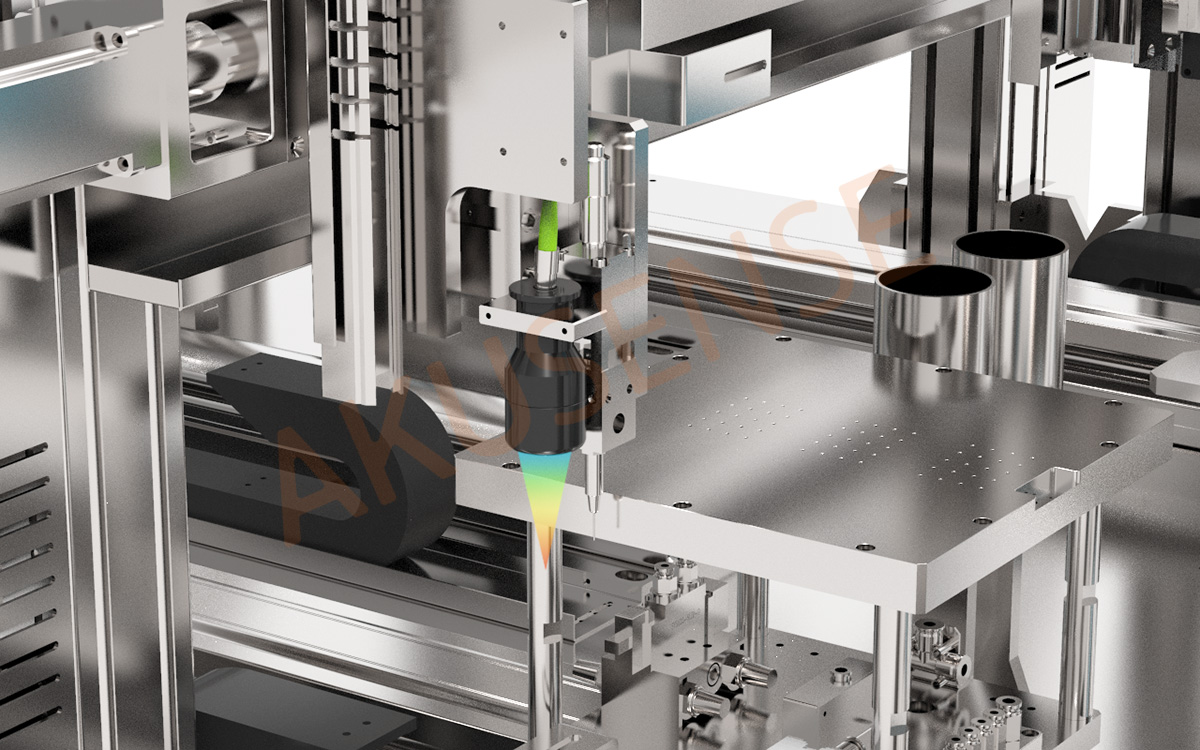

05 Height measurement of cell phone screens at dispensing stations - Confocal displacement sensor

For curved cell phone screens, poor angular characteristics can result in numerous anomalous positions that cannot be measured properly. Therefore, how to measure the curvature, flatness, thickness and 3D profile of curved glass to obtain its displacement information becomes a technical challenge for 3D curved screen dispensing. The Confocal Displacement Sensor (ACC-ADV) is a high-precision inspection tool that combines accuracy and efficiency with low requirements for the measured surface condition, allowing a larger tilt angle of the measured surface, fast measurement speed, and high real-time performance.

06 Cell phone screen undercutting - fiber optic sensor

Diffuse optical fiber is installed below the discharge line to detect product discharging. Due to the small thickness of the cell phone screen, it is necessary to use the fine optical fiber PD-F44U with the powerful fiber amplifier PG1 to achieve accurate measurement.

Akusense as an industrial sensing expert, has always focused on 3C electronics, new energy, semiconductor process, medical electronics and service robotics industries, and has built high quality sensors to provide professional complete solutions for automation equipment and testing industry, to escort users to become the industry leader.