The smart sensing solution is upgraded again! Make lithium battery winding machines more accurate and efficient

The smart sensing solution is upgraded again! Make lithium battery winding machines more accurate and efficient

With the continuous advancement of technology and the continuous growth of market demand, lithium batteries have become the mainstream technology in today's battery field. Driven by the rapid development of new energy vehicles, energy storage power statioWith the continuous advancement of technology and the continuous growth of market demand, lithium batteries have become the mainstream technology in today's battery field. Driven by the rapid development of new energy vehicles, energy storage power stations and other fields, the market size of lithium batteries continues to expand, which in turn drives equipment demand. The lithium battery equipment industry is undergoing technological upgrading and intelligent transformation, and efficient, intelligent, and automated equipment has become the mainstream of the market. Policy support, cost reduction and environmental protection requirements have also indirectly promoted the growth of demand for lithium battery equipment.

The winding machine is the core of the intermediate equipment for lithium battery cell manufacturing. The winding machine winds the die-cut pole pieces into lithium-ion battery cells. During the winding process, tension control accuracy, deflection correction ability, and winding efficiency have become the keys to the quality of the battery product.

The use of fully automatic equipment is of great help to the production efficiency and consistency of lithium battery products, and the selection of stable and precise sensor configuration plays a key role in equipment design.

Today I will share with you the workflow of the newly upgraded lithium battery winding machine and the application of sensors in the equipment~

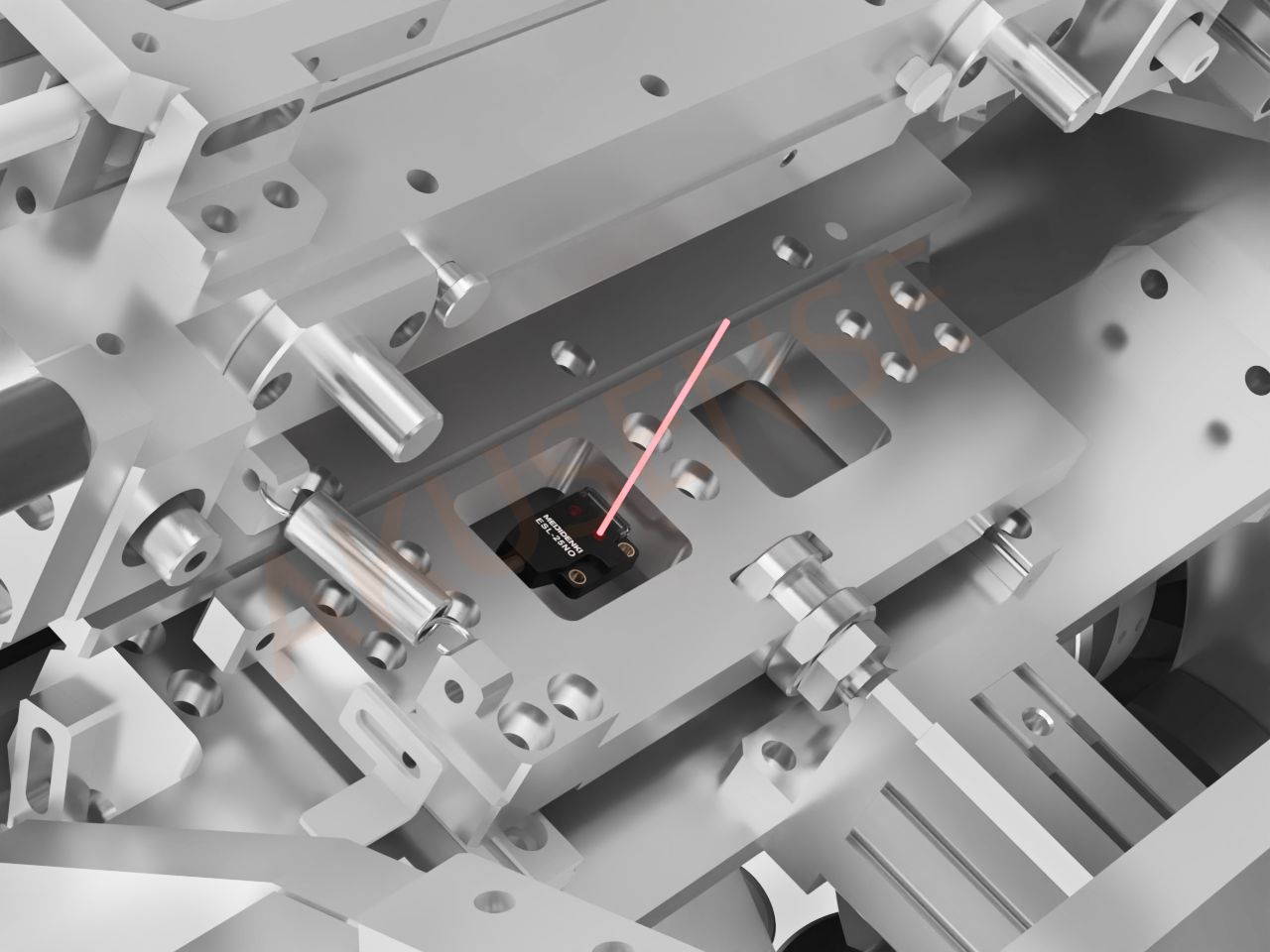

01 Check whether there is a lithium battery

Ultra-thin photoelectric sensor ESL-25NO

Application scenarios:

When the lithium electrode sheet is grasped to the transfer station with a narrow space, a sensor is required to detect whether there is a lithium battery on the fixture, and the response speed is required to be fast, less than 2ms.

solution:

1. Choose ultra-thin photovoltaic with a thickness of only 3.5mm, so you don’t need to worry about the narrow installation space.

2. Infrared light source and diffuse reflection detection principle can stably detect pole pieces.

3. Ultra-short response time ≤ 2ms

4. IP67 protection level, good dustproof and waterproof performance

02 Lithium battery pole piece single and double detection

MUD-60N-400 ultrasonic sensor

Application scenarios:

After the suction nozzle picks up the electrode pieces from the lithium electrode piece bin and transports them to the correction table, a sensor is required to detect single and double pieces of lithium electrode pieces. Single pieces will operate normally, and double pieces will alarm and shut down.

1. The area and thickness of the lithium electrode sheet is 3mm, and the weight is 500-800g/m^. Single and double sheets provide NPN switching signals.

2. The sensor response speed is required to be less than 30ms.

solution:

1. Select Meiji’s MUD series sensors specially used for single and double sheet detection, ultrasonic detection principle, non-contact detection

2. Can detect paper with a weight per unit area in the range of 20-1200g/m^

3. The detection distance can reach up to 60mm. Even if there are certain differences in the position of the material and jitter, it will not affect the actual detection effect.

4. The three detection modes of thick/thin/normal are adjustable and have a learning and teaching function, which can be quickly debugged to adapt to the detection of various specifications of materials on site.

5. Using high-frequency detection algorithm, the response time can be up to 6.5ms, which can realize high-frequency detection

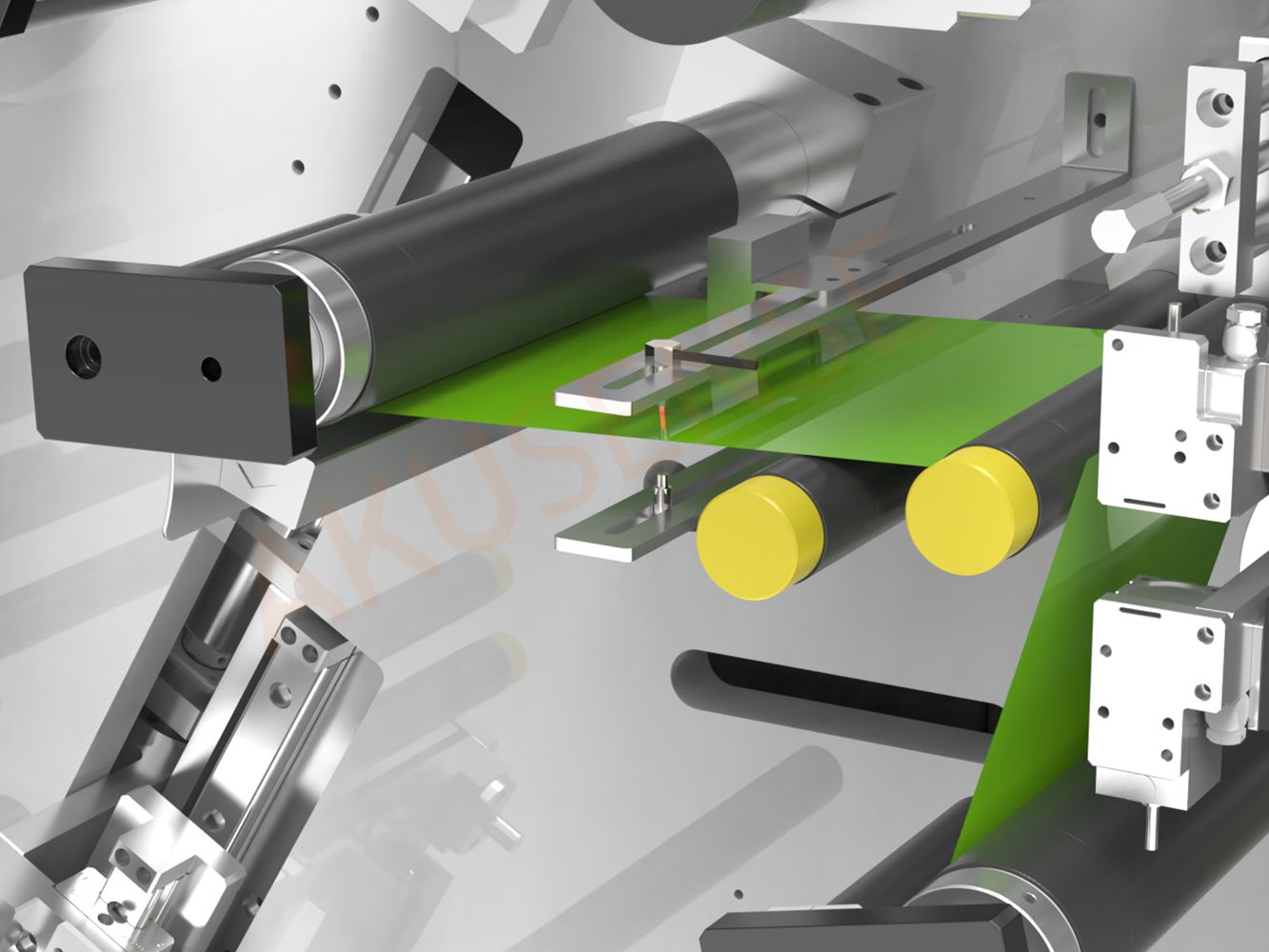

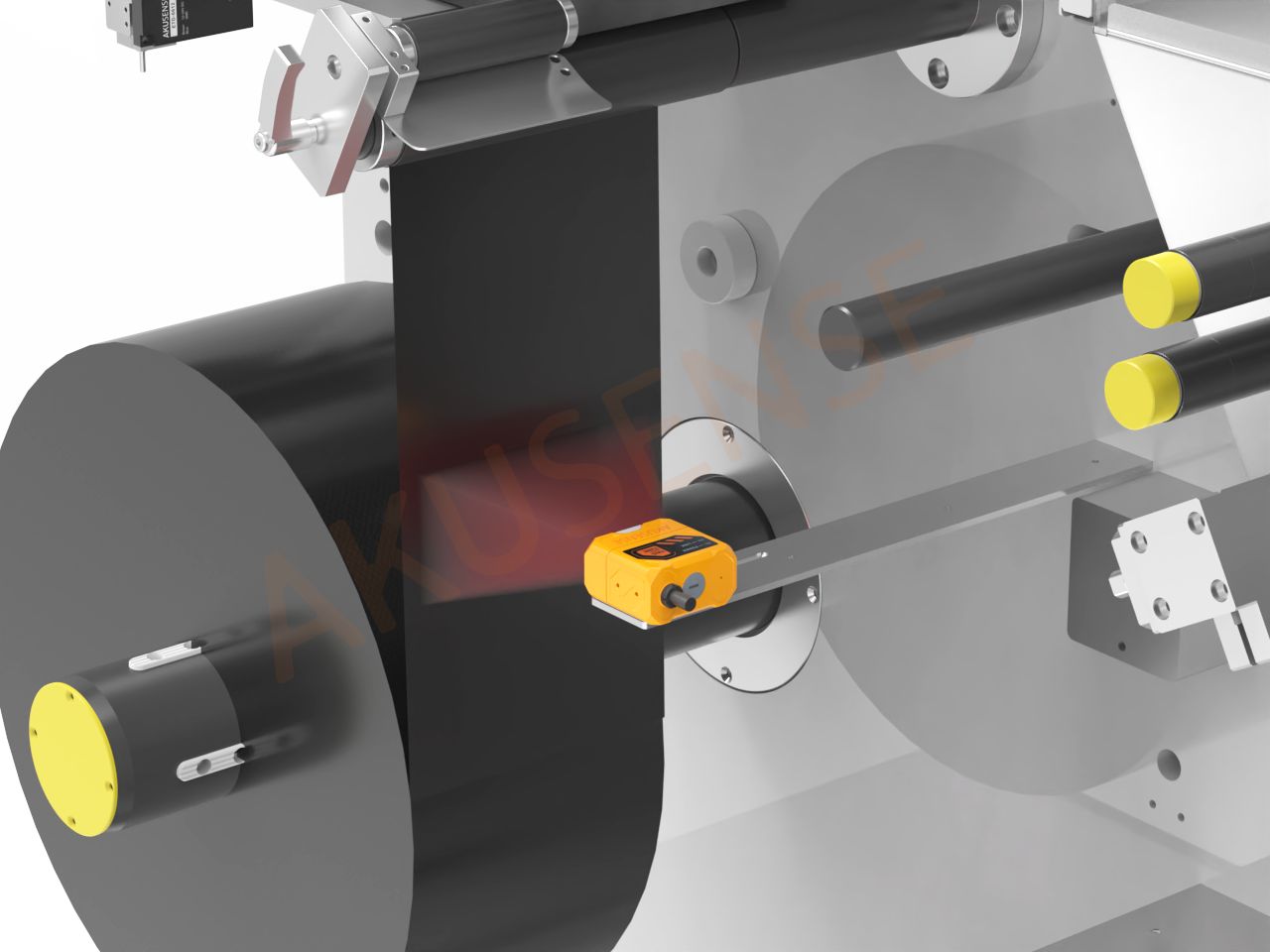

03 Monitoring of transmission status of pole piece and diaphragm

PE1+PD-32 fiber optic sensor

Application scenarios:

Sensors need to be used to monitor the transfer process of the positive and negative electrode sheets and separators of the battery in real time to avoid interruption of the sheet that affects subsequent processes.

solution:

1. Use high-precision diffuse reflection optical fiber components with amplifiers, install them above/below the battery pole pieces, monitor the presence of materials in real time, and feed the signals back to the PLC for control

2. The amplifier is adjustable in multiple gears, which can meet production and inspection requirements at different speeds.

3. With anti-interference control, multiple optical fiber sensors can be easily installed side by side and the detection effect is stable.

4. Corresponding cylindrical, regional matrix, flat bracket and other types of optical fiber components can be matched according to on-site installation conditions and mechanical operation requirements.

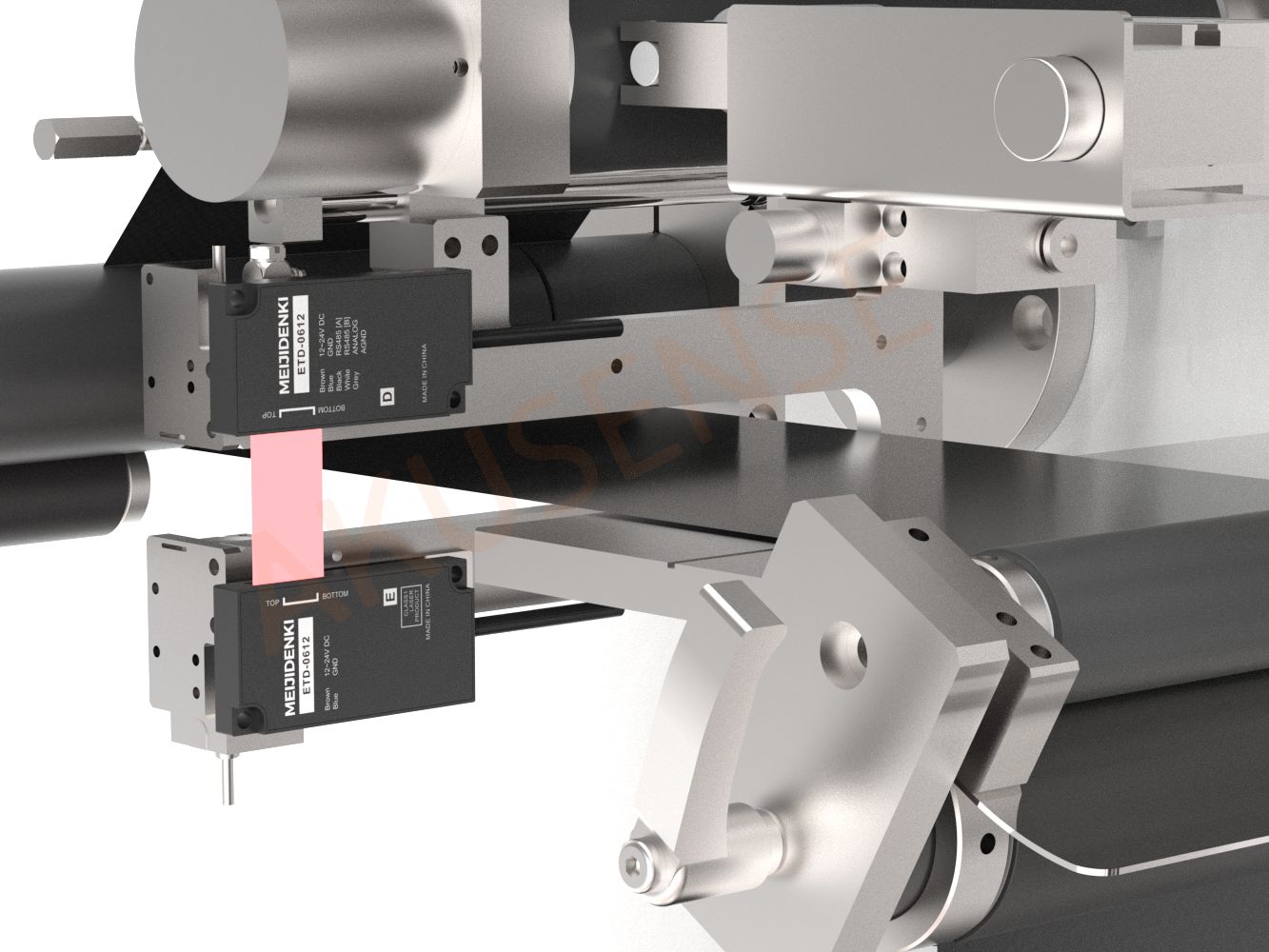

04 Diaphragm transmission deviation correction

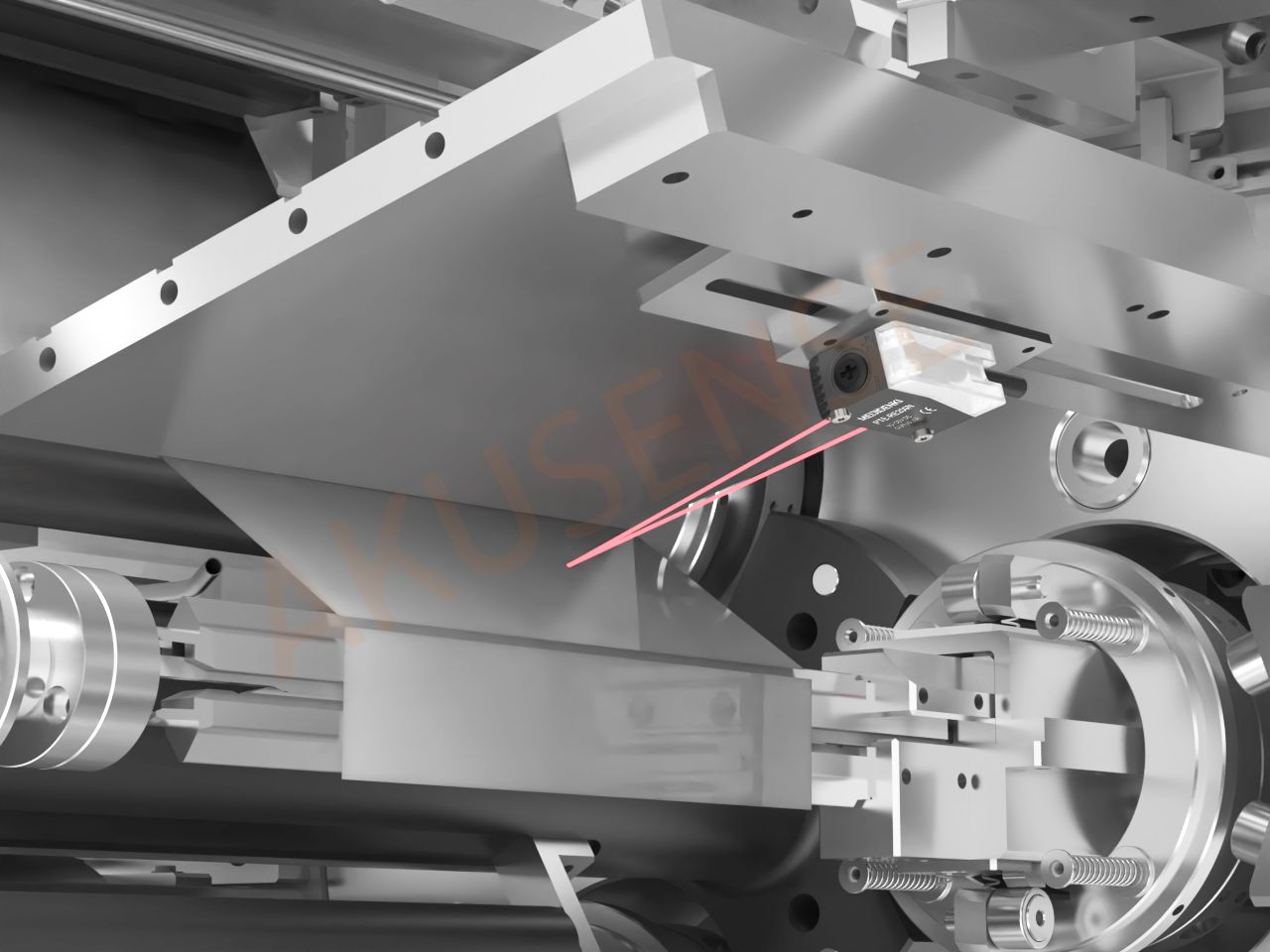

ETD-0612 Precision laser correction sensor

Application scenarios:

The deviation correction system is required to monitor the deflection of the left and right positions in the diaphragm transmission process in real time, and feedback the offset to the deviation correction control system to achieve precise position control during the diaphragm transmission process. The accuracy needs to be above the silk level to ensure the consistency of the winding. .

solution:

1. Use laser correction sensor ETD-0612 with controller

2. Adopt the laser area beam principle to achieve high-precision control of 1um

3. It can output analog voltage signals for direct signal interaction with the device's correction system to achieve real-time control of the diaphragm position.

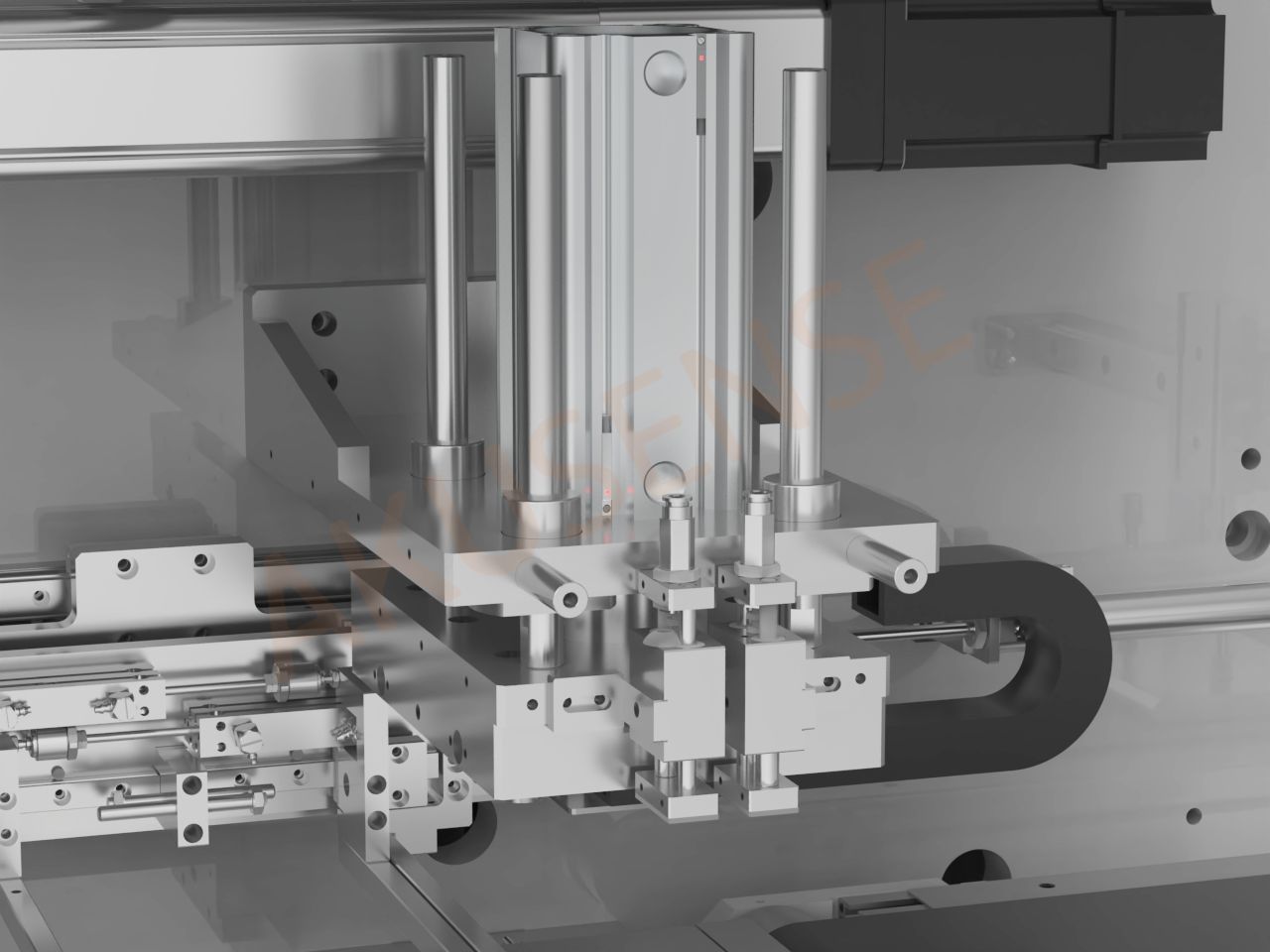

05 Movement mechanism limit

Slot sensor ST-303N-SW

Application scenarios:

The equipment's motion mechanism is complex, and groove sensors with various appearances such as F/T/R/L/K are widely used in multiple workstations of the equipment to perform position control such as positioning and limiting of the motion mechanism module.

solution:

1. Meiji has a rich product line of groove sensors, with 11 appearance options such as F/T/R/L/K, which can meet the installation requirements of different detection positions on the equipment.

2. The chip integration solution allows them to have a repeat positioning accuracy of 0.01mm, making the position control of the equipment more precise.

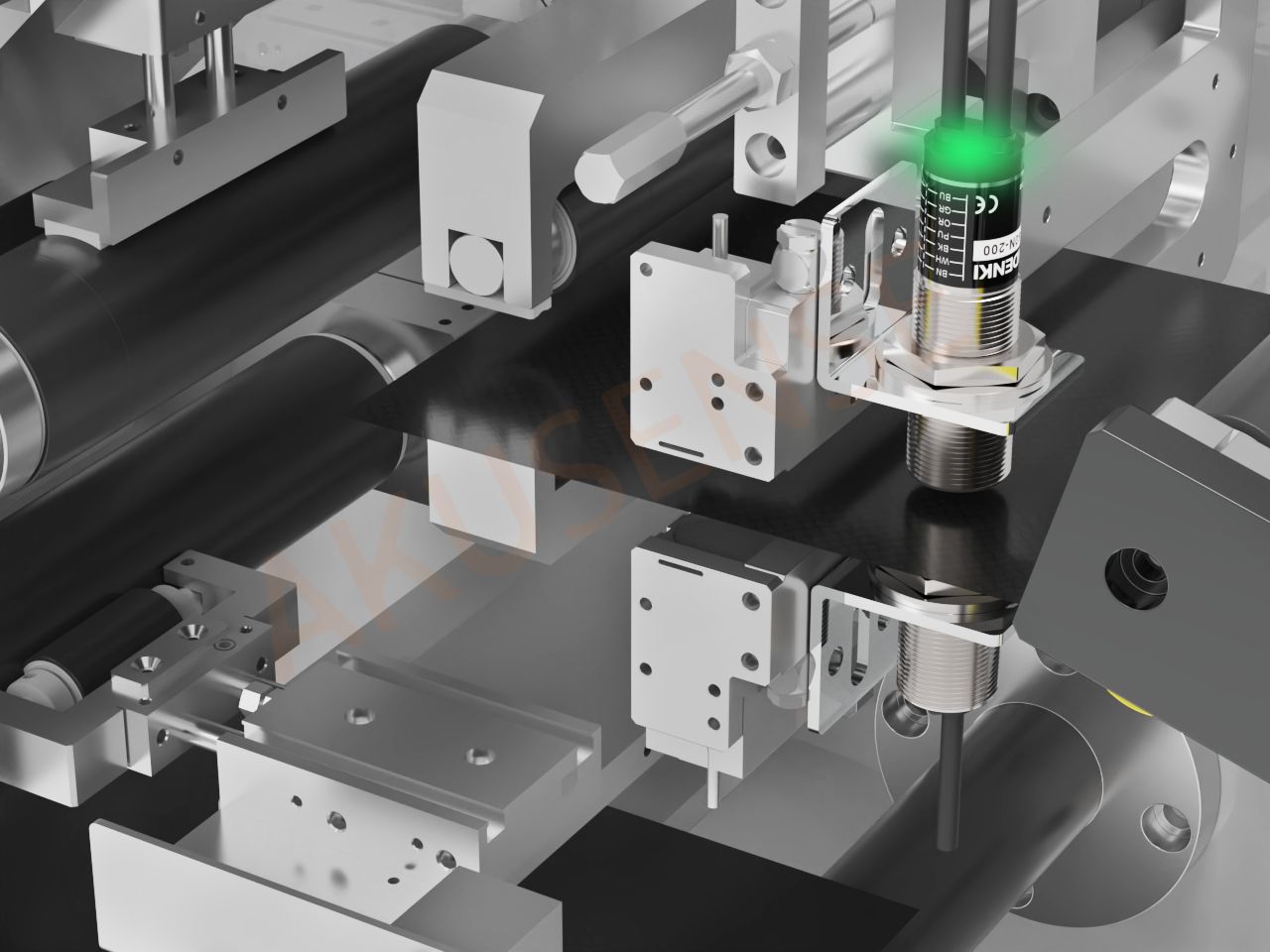

06 Fixture cylinder positioning

MR-C80 Magnetic Sensor

Application scenarios:

When the lithium electrode sheet is grasped to the transfer table, the positioning cylinder is extended to position the jig, and the extension movement of the cylinder is checked to see whether it is in place.

solution:

1. Select the MR-C80 magnetic sensor with high positioning accuracy and reliable performance, which has surge absorption protection function.

2. The maximum switching frequency can reach 1000Hz, and stable detection of high-speed scenes

3. Can be used in harsh environments such as vibration resistance/heat resistance (within 70℃)

4.IP67 protection level, dustproof and waterproof to reject various interference factors

5. Small size, can be integrated into various small installation environments

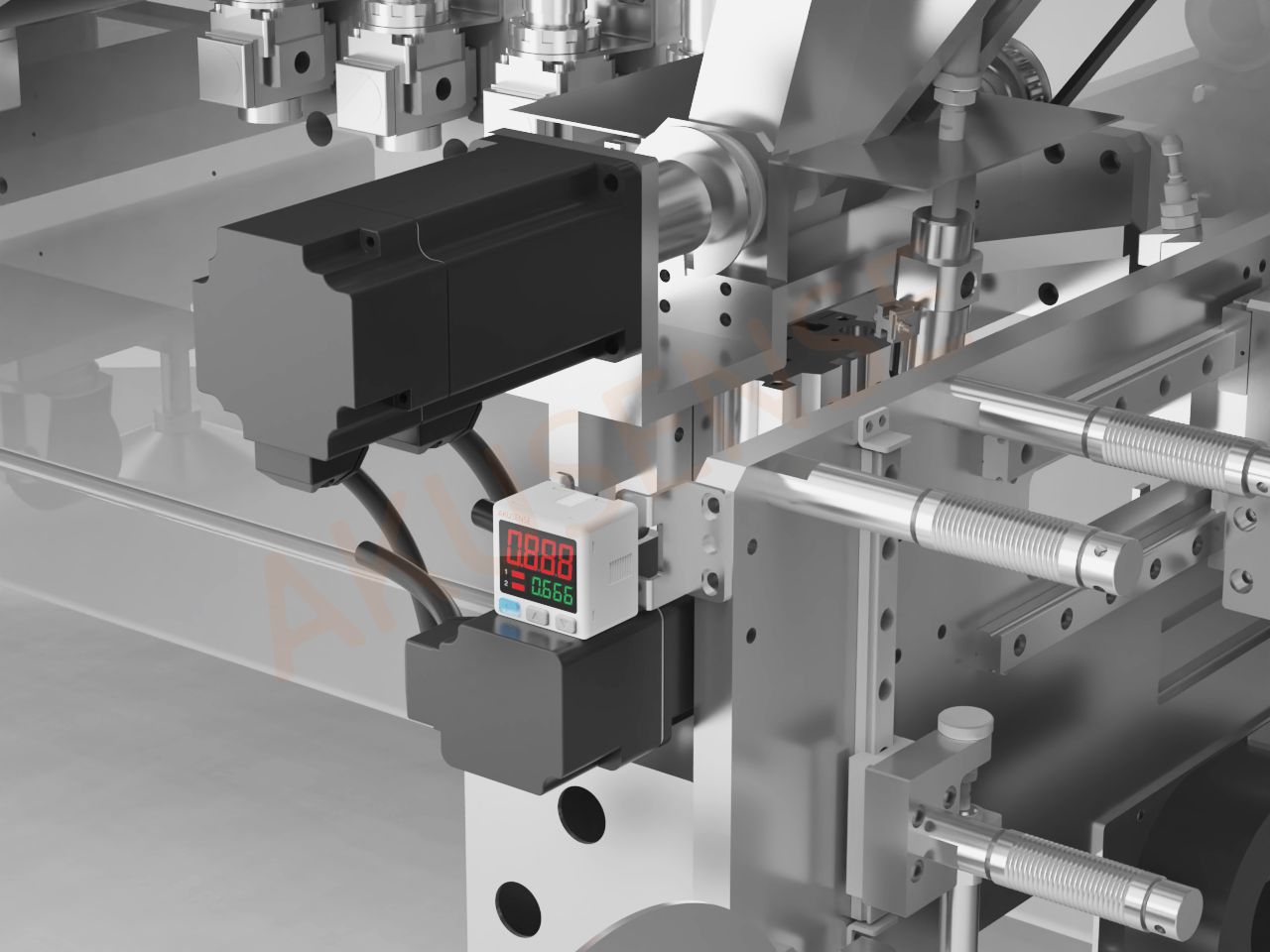

07 Nozzle positive and negative pressure detection

Digital pressure gauge MQ-02D

Application scenarios:

The suction nozzle sucks the electrode piece from the lithium electrode piece bin and transports it to the correction table. It is necessary to detect the positive and negative pressure of the suction nozzle to determine the pick-up and put-down action of the electrode piece. The detection pressure range is -50kPa~80kPa, current type 4 -20mA analog output

solution:

1. Use MQ-02D low-pressure digital display barometer

2. Pressure range -101.3~101.3kPa, maximum pressure resistance 500kPa,

3. Digital display type, simple and quick debugging

4. Comes with installed sheet metal, easy to install

08 Safety door protection

Security door lock AR3 series

Application scenarios:

The detection distance is 12mm. It is necessary to ensure that the safety door is closed in place and is normally open. When the safety door opens, the equipment stops; when the safety door closes normally, a completion signal is given to the PLC, and the equipment operates normally.

solution:

1. Optional safety door lock AR3 series

2. Built-in multi-contact structure is available, and a variety of metal heads are available

4. The locking force is 1300N and has excellent resistance to strong pull.

5. IP67 protection level, good waterproof and dustproof performance

6. Standard gold-plated contacts can be used with general negative or micro loads.

09 The battery core roll is in place

Photoelectric sensor PTE-DV100

Application scenarios:

After the positive and negative electrode materials and separators are rolled into small battery cells, tape needs to be attached to prevent the battery core from loosening or shifting. Here, a square photoelectric detector needs to be used to detect that the battery core roll is in place, thereby sending out a signal to proceed to the next step. Gluing operation.

solution:

1. Use infrared light source, high sensitivity PTE-DV100

2. Response time 1.6ms

3. Diffuse reflection detection principle, detection distance 1000mm

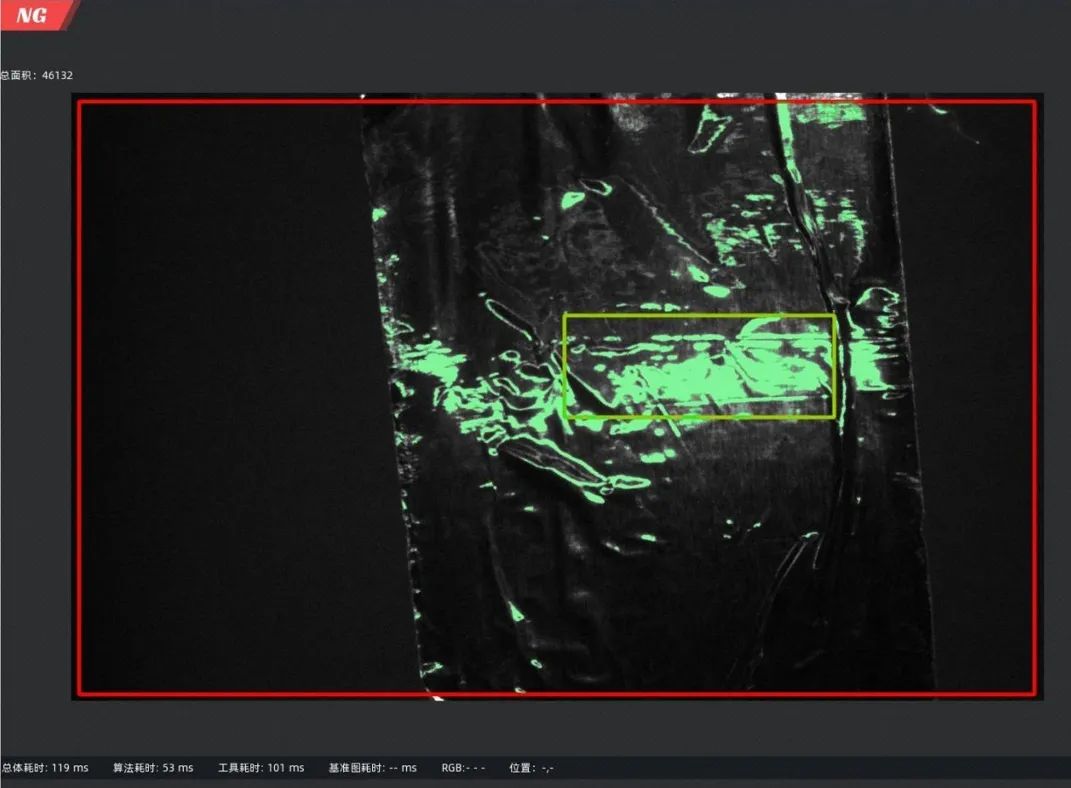

10 Check whether there is a label on the pole piece

Vision sensor VDS10-BQ0106-WP

Application scenarios:

There are logos of various colors (silver, green, yellow, blue) on the pole pieces. You need to identify the pole pieces with the logo.

Current speed: 850mm/s

The total width of the pole piece is 160mm, and half of it needs to be covered

solution:

Meiji Vision standard product VDS10 series is selected for detection. The detection principle is to highlight the characteristic area under camera imaging to determine the presence or absence of tape.

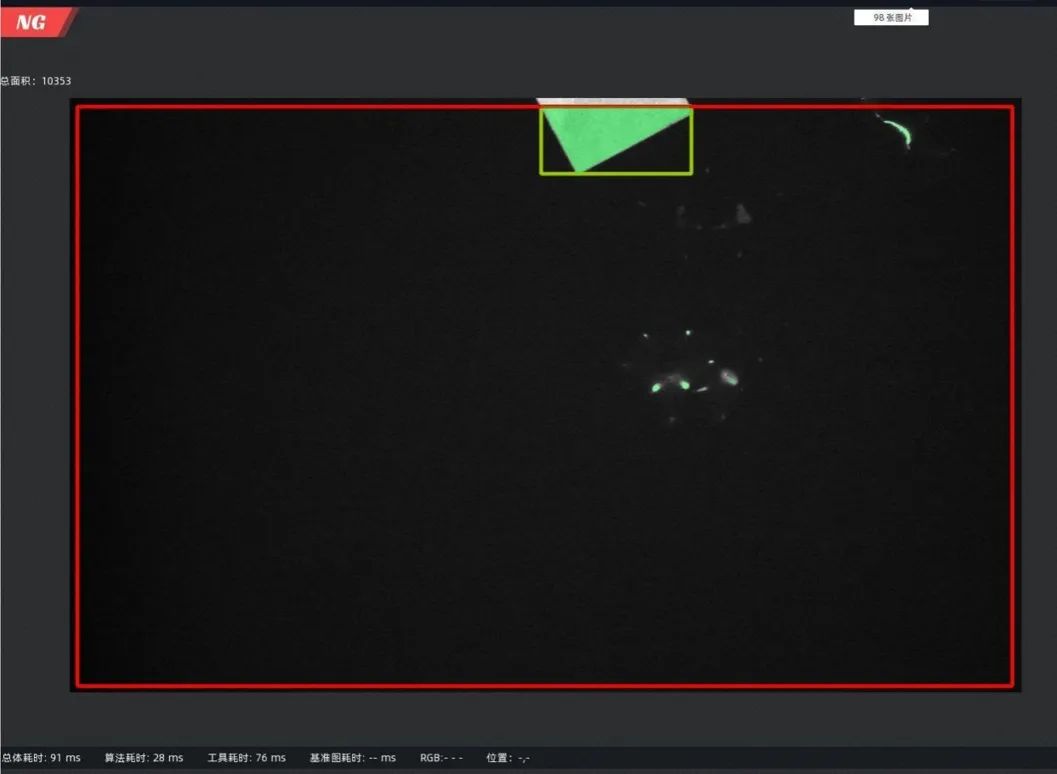

Imaging effect:

OK

The above is a normal image with no bad targets.

There will be a little light feedback when installed vertically, which does not affect the judgment result. OK

NG

Except for transparent tape, the images of tapes of various colors are highlighted and can be recognized as NG.

NG

Only a small portion of the tape can be identified as NG within the detection range

Four sets of sensors on one piece of equipment can be integrated on your company's equipment through the monitoring system. Convenient for real-time observation. At the same time, NG pictures also have a storage function for feedback and analysis.

With the continuous development of technology, Meiji will have more types of sensors applied to lithium battery winding machines in the future to further help improve the winding efficiency and battery quality of the equipment.